|

Bob's Shop Notes: |

|

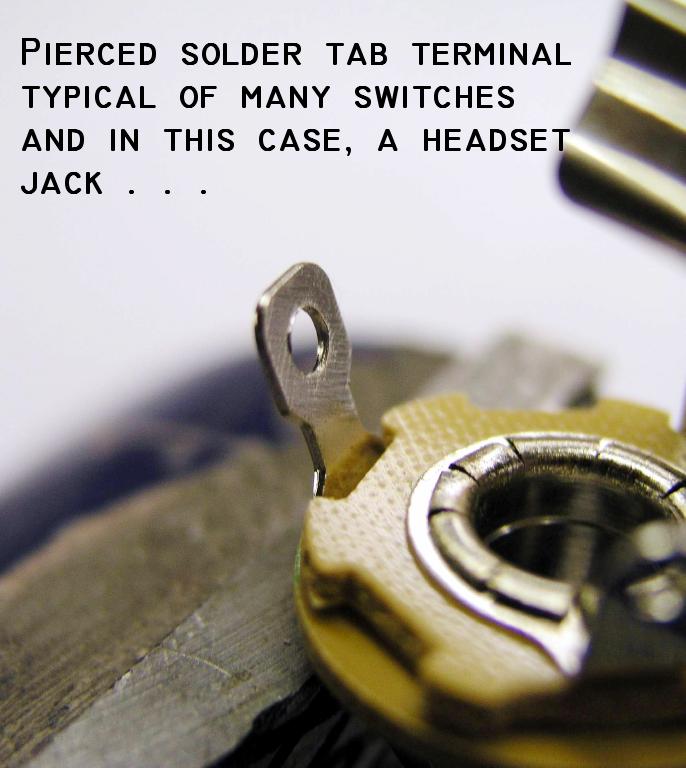

Many system components come with terminals designed to accept soldered wires for connection. The terminals may be simple posts, tabs, pierced tabs, etc. The headset jack illustrated here offers pierced tabs . . . |

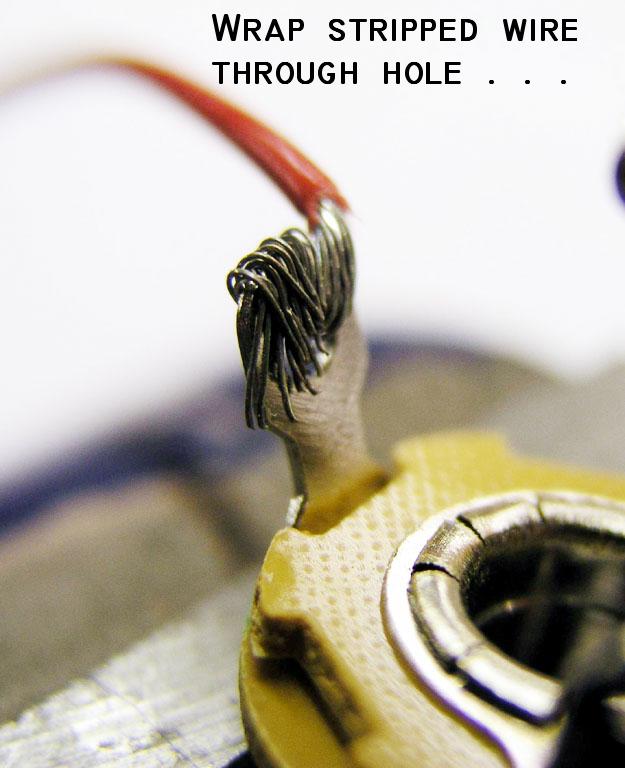

| Strip the wire with sufficient exposure of strands to extend through the hole and wrap around the terminal edge as show. |

|

|

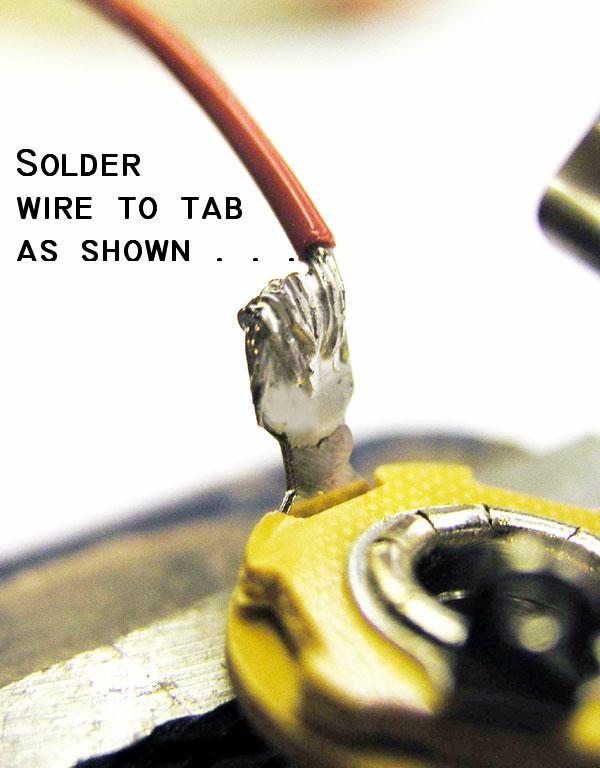

Complete the joint with electronic grade solder. 60/40, 63/37 with a non corrosive flux. Kester Resin "44" or "285" are both good as are many others. |

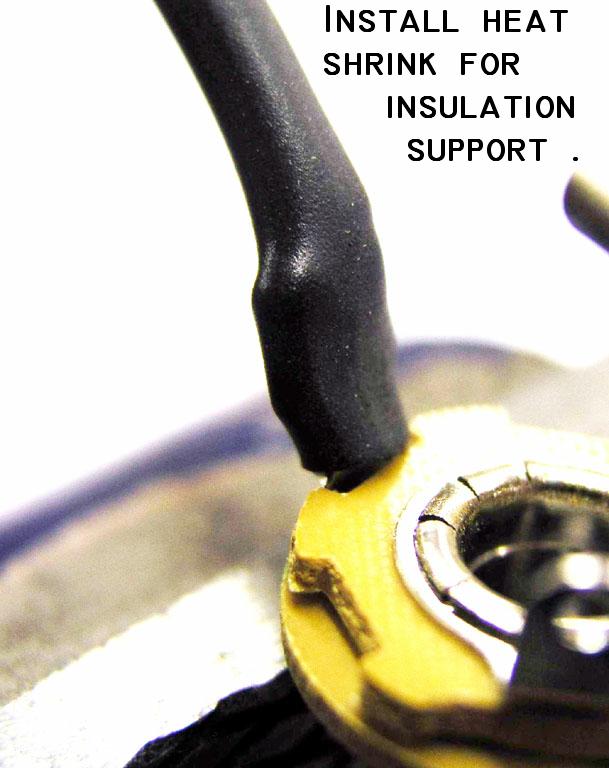

| After soldering, cover joint with heatshrink for insulation support. Heatshrink large enough to fit over the tab may not shrink sufficiently to grab the wire. It's a good idea to put a short piece of smaller heatsrhink over the wire to build its diameter. This same technique applies to any device with similar, solderable terminals. |

|